When we talk about shackles on boats, their load ratings—or Working Load Limit (WLL)—tell us the max weight they safely bear. Think of it as the shackle’s “golden rule.” Ignoring it can lead to gear snapping, and nobody wants to be tossing anchors in panic! These ratings, stamped right on the shackle, depend on materials like stainless steel and how they’re made. We’ll explore how to spot these marks, keep shackles in tip-top shape, and pick the right ones so your boating stays smooth and safe.

Key Takeaways

- Shackles have load ratings marked on their body and pin indicating the maximum safe load capacity.

- Working Load Limit (WLL) must not be exceeded to prevent shackle failure and accidents.

- Ensure load distribution is even; uneven loads can weaken shackles even below the rated limit.

- Verify load ratings are clear and from a trusted manufacturer for reliable safety assurance.

- Regularly inspect shackles for wear, corrosion, or damage to maintain load rating integrity and safety.

Types of Shackles Commonly Used in Boating

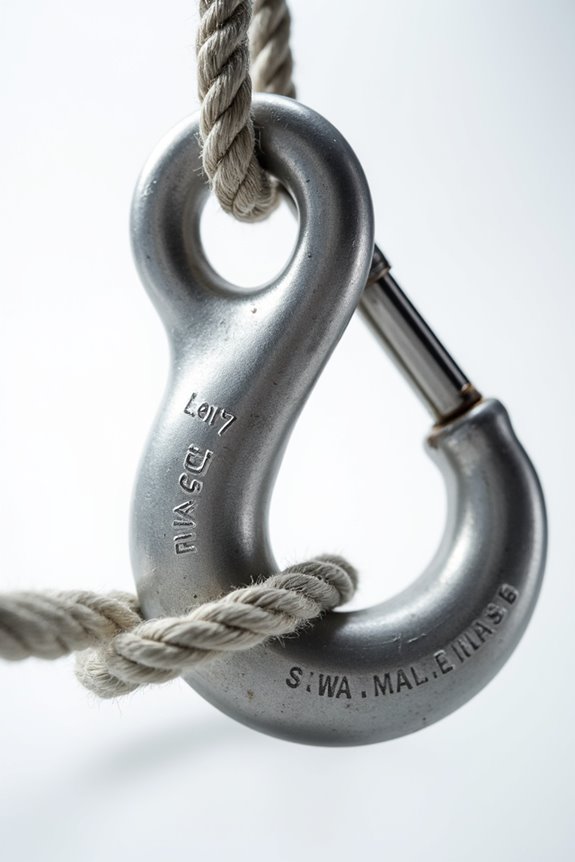

When it comes to boating, shackles might not be the flashiest gear on your boat, but they’re absolutely essential. We’ve all seen them—those sturdy metal loops with pins—but did you know there are plenty of shackle variations designed for specific shackle applications? Take anchor shackles, for example; they’re built tough to connect anchors to chains, handling heavy loads without breaking a sweat. Then there’s the bow shackle with its roomy bow, perfect for multiple connections or side loading. Don’t forget D-shackles, great for straight-line pulls, and chain shackles designed to link chains or attach them to fittings, especially in towing or mooring. Whether you’re tightening halyards or securing the anchor, knowing these shackle types helps us pick the right one, keeping our gear—and us—safe out there.

Importance of Working Load Limit in Shackle Safety

Although shackles might seem like simple gear, understanding their Working Load Limit (WLL) is essential for keeping us safe out on the water. The WLL tells us the maximum load a shackle can handle without risking shackle failure. Think of it as a safety speed limit; pushing beyond it can lead to accidents—or worse, gear failure right when we don’t want it. Proper load distribution matters too, since uneven forces can weaken the shackle’s effectiveness, even if we stay below the WLL. By sticking to these limits and keeping those loads balanced, we protect not just our equipment but everyone aboard. So, next time you pick a shackle, remember the WLL—because safety starts with knowing your gear’s limits. Who knew numbers could save lives?

Materials and Construction Methods for Shackles

While it might seem like shackles are all made the same, the materials and construction methods behind them actually play a huge role in how well they perform—and how long they last. We need to take into account material properties like tensile strength and corrosion resistance, which vary between carbon steel, alloy steel, and stainless steel. Ever wonder why forging matters? That’s a manufacturing process where heat treatment greatly boosts strength and impact resistance, making shackles tougher and safer. Casting is common too, but it doesn’t offer the same durability. Plus, surface coatings like galvanizing protect against rust, especially in marine settings. So, picking the right shackle isn’t just about size—it’s about knowing how its material and manufacturing processes suit our specific boat and environment needs. Safety first, right?

How to Identify and Interpret Shackle Load Ratings

Because knowing how to spot and read shackle load ratings can save us from costly mistakes—or worse, accidents—it’s worth paying close attention to the markings stamped right on the shackle. These shackle markings usually include the manufacturer’s name, the size, and the rated load, either in short tons (uppercase T) or metric tons (lowercase t). Both the shackle body and the pin carry these essential details, ensuring load visibility that shouldn’t fade over time. Think of these markings as your shackle’s ID card—without them, how can we trust it to handle the weight? If the load rating’s unclear, it’s a red flag waving loudly, and we shouldn’t push our luck. So next time you pick up a shackle, take a moment to read the stamps—they’re there to keep us safe out on the water.

Inspection and Maintenance Practices for Shackles

Since shackles are the unsung heroes holding everything together in lifting and rigging, giving them a good once-over before and after use isn’t just smart—it’s essential. We all know that shackle wear can sneak up fast, so how often should we inspect them? Well, inspection frequency depends on usage and conditions. Daily visual checks help spot obvious damage like corrosion or bending before they cause trouble. For heavier use or harsh environments, monthly to quarterly thorough inspections are wise. Remember, if wear exceeds 10% of original size, it’s time to retire that shackle. Maintenance isn’t just about checks—regular cleaning, lubrication, and securing pins all keep shackles working smoothly. Trust us, nothing beats smooth-operating gear on deck—not even the best fishing tales!

Compliance With Safety Regulations and Industry Standards

Now that we’ve covered how to keep shackles in good shape with regular inspections and maintenance, let’s talk about the rules that keep everyone safe on the job. Regulatory compliance isn’t just paperwork—it’s our safety net. OSHA standards require clear Working Load Limits (WLL) marked on every shackle to prevent overload—because who wants surprise failures? We all have to stay sharp with daily checks and prepare for safety audits that verify these rules are followed. Remember, using damaged or incorrectly marked shackles can lead to fines and, worse, accidents. Plus, industry standards like ASME B30.26 guide us on proper use, materials, and installation—think of it as the rigging rulebook we all play by. So, sticking close to these standards is not just smart; it’s how we look out for one another.

Best Practices for Selecting and Using Shackles Safely

While it might seem straightforward to just grab any shackle off the shelf, selecting the right one is actually a bit like picking the perfect pair of shoes—you want the fit, strength, and style to match your job. First, avoid pin-to-pin shackle connections; bow-to-bow or bow-to-pin is safer and stronger. Ever heard of side loading? It’s a big no-no for D-shaped shackles, but anchor shackles can handle it—just be careful. Make sure your shackle’s Working Load Limit matches the task and the wire rope diameter. Regularly inspect for wear and corrosion, and choose materials like stainless steel for marine environments. After all, we’re all in this boating adventure together, so let’s keep our gear—and ourselves—safe and sound. Who knew shackles could be so social?

Frequently Asked Questions

How Does Temperature Affect Shackle Load Ratings in Extreme Boating Conditions?

Much like sailors once relied on constellations, we must trust shackle temperature effects to guide us through extreme conditions. High heat lowers load capacity, cold risks brittleness—it’s our shared duty to respect these limits for safe voyages together.

Can Coatings or Paints Impact the Structural Integrity of Shackles?

We understand coating durability and paint adhesion are vital—they protect shackles from corrosion, helping maintain structural integrity. By sticking together and inspecting regularly, we guarantee our gear stays safe and strong for all our adventures.

What Are the Environmental Impacts of Disposing Worn-Out Shackles?

Imagine a coral reef suffering from discarded shackles rusting away. Together, we can support shackle recycling and follow environmental regulations to protect these waters, fostering a community dedicated to preserving marine ecosystems for future boaters like us.

How to Choose Between Forged and Cast Shackles for Specific Marine Applications?

When choosing shackles, we trust forged advantages like higher strength and fatigue life, which beat cast disadvantages such as brittleness and shorter lifespan. Together, let’s prioritize safety and durability in our marine adventures by choosing wisely.

Are There Digital Tools Available to Calculate Shackle Load Safety Margins?

Yes, we can use digital shackle calculators for safety margin analysis, helping us guarantee accuracy and reliability. These tools let us input loads and shackle specs, fostering confidence and shared safety in every load-bearing situation.