Deck cranes are like the multitaskers of heavy lifting, designed with compact, wheeled bases and outriggers for steady, precise moves—even in tight spots. They handle loads ranging from 2.5 to 22 tons, depending on the boom length and support. Whether it’s hauling steel or moving cargo on ship decks, we rely on their versatile designs—like knuckle or telescopic booms—to get the job done safely and efficiently. Curious about how safety and maintenance keep these machines humming?

Key Takeaways

- Deck cranes feature compact, low-profile designs with 360-degree rotating booms for precise load handling in confined spaces.

- Load capacities typically range from 2.5 to 22 tons, with smaller models suited for tight areas and larger cranes for heavy industrial lifts.

- Types include knuckle boom, telescopic boom, hydraulic, and electro-hydraulic cranes tailored for various marine and industrial applications.

- Safety protocols emphasize operator training, pre-operation checks, load adherence, and use of standardized signaling to prevent accidents.

- Regular maintenance and thorough inspections, including daily, weekly, and annual checks, ensure crane reliability and safe operation.

Overview of Deck Crane Design and Functionality

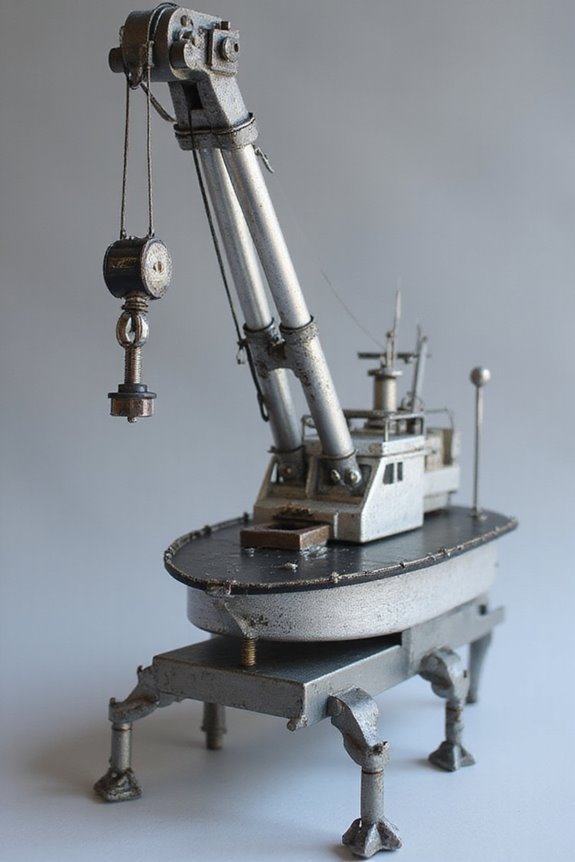

When you dig into deck crane design, you’ll find they’re built to be surprisingly versatile yet straightforward—that’s no accident. These cranes tackle operational challenges with smart design innovations, like their low-profile, compact build that squeezes into tight spots and under low ceilings. Plus, their wheeled, mobile base—with outriggers for stability—lets us move loads smoothly without flipping a table or two. Ever wonder how they maintain control? The operator’s cab is placed just right for max visibility, while joysticks handle precise hydraulic lifts. And with 360-degree rotating booms, deck cranes easily position loads exactly where needed. From the customizable driveline options to secure decks that prevent shifting, these cranes balance power and finesse, proving they’re not just workhorses, but clever problem solvers on any site.

Common Applications of Deck Cranes Across Industries

Now that we’ve seen how deck cranes are designed to be nimble, strong, and precise, you might wonder where all that clever engineering really shines. Deck crane applications span many fields—from hauling steel on tight construction sites and easing machine maintenance in factories, to moving heavy cargo at shipyards. Ever tried lifting something huge in a cramped warehouse aisle? That’s another industry specific use deck cranes excel at. Mining operations and heavy industry rely on them to handle tough loads in rough conditions, too. These cranes aren’t just muscle; their precision and portability make them invaluable partners across industries. So, whether it’s loading containers or assembling bridges, deck cranes prove their worth by blending strength, flexibility, and smarts—making tough jobs a bit easier, and maybe even a little fun.

Types of Deck Cranes and Popular Models

Deck cranes come in a bunch of different shapes and sizes, each tailored for specific tasks and environments—kind of like tools in a handy toolbox. We’ve got knuckle boom cranes with their bendy arms perfect for tight ship decks, and telescopic boom cranes that stretch out far for offshore work. Ever heard of hydraulic or electro-hydraulic cranes? They’re the powerhouses behind smooth, precise moves, boosting crane efficiency while keeping operational safety outstanding. When it comes to popular models, MacGregor’s GLB and GLH series stand out, handling anything from moderate to heavy loads with ease. Choosing the right deck crane isn’t just smart—it’s how we guarantee safe, efficient lifting every time—and who doesn’t want that kind of reliability on board?

Load Capacity Ranges in Carry Deck Cranes

Although carry deck cranes come in all sorts of configurations, their load capacities tend to fall within a pretty manageable range—usually between 2.5 and 22 tons. We’ve got everything from small 2.5-ton models ideal for tight spots, to beefier cranes pushing close to 20 tons for heavier lifts. This range hits a sweet spot, balancing compact design with solid lifting power to boost operational efficiency on-site. Ever wonder how they work so smoothly in cramped areas? That’s partly thanks to their hydraulic controls and truck-like maneuverability. Whether you’re handling rooftop installs or heavier industrial loads, knowing which load capacity fits your job helps us all work smarter, not harder — and keeps the whole team feeling confident and safe.

Influence of Boom Length and Outriggers on Capacity

When we start talking about boom length and outriggers, it’s easy to overlook just how much they shape a crane’s lifting capacity. As we extend the boom length, the lifting radius grows, but that also cramps our lifting capacity, thanks to the extra leverage and stress on the crane’s structural integrity. That’s where outrigger extension steps in—fully extended outriggers broaden the base, boost load stability, and help keep those safety margins in check. Skimp on outriggers, and you risk tipping or busting operational limits. So, balancing boom length with proper outrigger deployment is key to managing crane dynamics effectively. It’s like teamwork; one tool alone can’t pull the job off safely, but together, they let us lift smarter, not harder. Ready to keep it steady?

Key Specifications Affecting Load Limits

Since our goal is to lift safely and efficiently, it’s essential to understand the key specs that directly affect a crane’s load limits. One big factor is load distribution—how the weight spreads across the crane can make or break its capacity. Ever wonder why some cranes stand steady while others wobble? That’s where structural design steps in. Deck cranes often use high-strength alloy frames to handle stress without flexing dangerously. The design includes features like integral outriggers that help balance and stabilize loads, making sure we don’t push the limits—or the crane! So, when choosing or operating a deck crane, pay close attention to these specs. They’re not just numbers; they’re the foundation of safe lifting and smooth operation. After all, we want to get the job done without turning it into a circus act.

Marine Deck Cranes and Specialized Configurations

While marine deck cranes all share the goal of lifting heavy loads safely on water, their designs can vary quite a bit depending on the vessel and task at hand. We see specialized configurations tailored for marine applications everywhere—from knuckle boom cranes with motion compensation that keep operations smooth in choppy seas, to telescopic booms that reach further but tuck away neatly when not needed. Ever heard of folding boom cranes? They’re perfect for tight quarters on smaller vessels, saving precious deck space. And some setups are so custom, they even match yacht aesthetics—functional and fancy! Whether it’s dual cranes working together or self-erecting units for quick deployment, marine deck cranes prove there’s no one-size-fits-all. It’s all about choosing the right tool that fits the mission and keeps us afloat, literally and figuratively.

Safety Practices for Operating Deck Cranes

Although deck cranes make heavy lifting look easy, operating them safely takes more than just muscle and a steady hand—it requires training, checks, and clear communication. That’s why operator training is non-negotiable; it covers everything from crane components to essential safety protocols. Before we even think about lifting a load, daily pre-operation checks are a must—checking fluid levels, tire condition, and ensuring all safety gear is ready to go. Ever tried moving a massive load without knowing the exact limits? Not fun—and dangerous. We stick to load capacities and use standardized hand signals to keep everyone in sync. Plus, ongoing education keeps us sharp and ready for whatever challenges the job throws at us. Safety isn’t just protocol; it’s how we look out for each other on deck.

Advances in Drive Systems and Control Mechanisms

We all know how important safety is when handling deck cranes, but let’s face it—how those cranes move and respond is just as important for keeping things smooth and efficient. Thanks to drive system innovations, electric and hybrid drives now reduce noise and emissions, making our work environments friendlier. Control mechanism advancements have integrated electronics, hydraulics, and sensors to deliver precise, real-time feedback on load weight and wind conditions. Ever used a wireless remote to move a load from a safe distance? That’s a game-changer for operator safety and flexibility. These smart systems don’t just make crane operation easier—they boost reliability and help us meet stricter environmental rules. So, embracing these tech upgrades isn’t just smart; it’s how we all stay ahead together.

Maintenance and Inspection for Optimal Performance

Since deck cranes work hard in tough conditions, keeping them running safely and smoothly means staying on top of maintenance and inspections. We all know how vital preventive maintenance is—like daily visual checks on ropes and controls, weekly tests of brakes and limit switches, and seasonal lubrication for hydraulics. Following thorough inspection protocols isn’t just about ticking boxes; it’s about protecting everyone on deck. Have you ever wondered what happens if we skip those monthly reviews of bolts or the annual thorough examinations with certified pros? Not a pretty picture. Let’s keep those wire ropes fray-free, brakes responsive, and emergency stops reliable. By logging every check and repair, we create a safety net that supports our whole crew. After all, a well-maintained crane is a happy crane—and a safer one, too.

Frequently Asked Questions

How Are Deck Cranes Transported Between Job Sites?

Ever wonder how massive deck cranes journey between sites? We rely on deck crane logistics using transport methods like trucks, heavy haulers, and specialized trailers, ensuring everything moves safely while keeping our team connected to the process.

What Training Certifications Are Required for Deck Crane Operators?

We understand operator qualifications are essential, so we guarantee deck crane operators get certified through NCCCO or similar programs. Following safety protocols keeps us all safe and compliant, making us a skilled, trusted community in crane operation.

How Do Weather Conditions Affect Deck Crane Operations?

We understand wind effects can destabilize cranes, causing dangerous swings, while rain impacts traction and safety. Together, these weather challenges remind us to work closely, staying cautious and supporting each other for safe crane operations.

What Are the Environmental Impacts of Using Deck Cranes?

We recognize that deck cranes contribute to noise pollution and emissions, but together we can drive emission reduction by adopting cleaner, quieter technologies and following best practices, creating a safer environment we all belong to and protect.

Can Deck Cranes Be Customized for Unique Lifting Tasks?

Imagine a deck crane tailored like a bespoke suit; we embrace custom design to boost lifting efficiency, ensuring every task fits us perfectly. Together, we lift smarter, feeling confident in our shared precision and strength.