Optimizing your yacht’s engine room ventilation is all about smart airflow—fresh air should enter low and forward, while hot air exhausts high and aft. We calculate vent sizes based on horsepower, adding extra for bends or louvers, and double that for twin engines. Keeping the temperature within 30°F above outside is key to avoiding overheating and moisture issues. Plus, proper sealing keeps nasty fumes out. Curious how these small tweaks keep things running cool and safe? There’s more to uncover ahead.

Key Takeaways

- Position fresh air intakes low and forward, with exhaust vents high and aft, to maximize airflow and heat removal efficiency.

- Calculate vent area based on total horsepower divided by 3.3 square inches, adding 20% for duct resistance and doubling for twin engines.

- Use high-volume fans and ducting to direct cool air to engine parts and remove hot air effectively, preventing hotspots and overheating.

- Maintain slight negative pressure in the engine room to prevent fumes from entering living spaces and ensure air quality.

- Control temperature and moisture by limiting engine room temperature rise to 30°F above outside, using seawater cooling, filtration, and proper drainage.

Understanding Key Principles of Engine Room Ventilation

When it comes to engine room ventilation, there are a handful of key principles we all need to keep in mind to keep things running smoothly—and safely. Understanding airflow dynamics is essential; fresh air must enter low, away from heat sources, while exhaust vents sit high to pull out hot air effectively. This arrangement prevents stale pockets that could lead to overheating or dangerous vapor buildup. Ventilation efficiency isn’t just about moving air—it’s about where and how it moves, ensuring cool air doesn’t blast directly onto hot engine parts. Have you noticed how keeping air flowing properly protects hoses and belts from heat damage? Plus, it stops condensation that could cause corrosion. Together, these principles aren’t just rules—they’re our shared blueprint for a safe, efficient engine room environment.

Designing Effective Ventilation for Yacht Engine Rooms

Although engine room ventilation might not be the most glamorous part of yacht design, it’s absolutely vital for keeping your engine happy and healthy. When we talk about designing effective ventilation for yacht engine rooms, it’s all about smart ventilation system layouts and airflow direction optimization. We want fresh air entering low and forward, while hot exhaust air exits higher and aft, preventing that dreaded recirculation of heat. Maintaining a slight negative pressure helps pull air efficiently without allowing fumes to sneak into living spaces—because no one wants to smell their engine, right? Calculating enough vent area guarantees we meet the engine’s airflow needs, and sealing up tight keeps contaminants out. So, when it comes to design, it’s a balance of science and subtlety to make certain your engine runs cool and quiet.

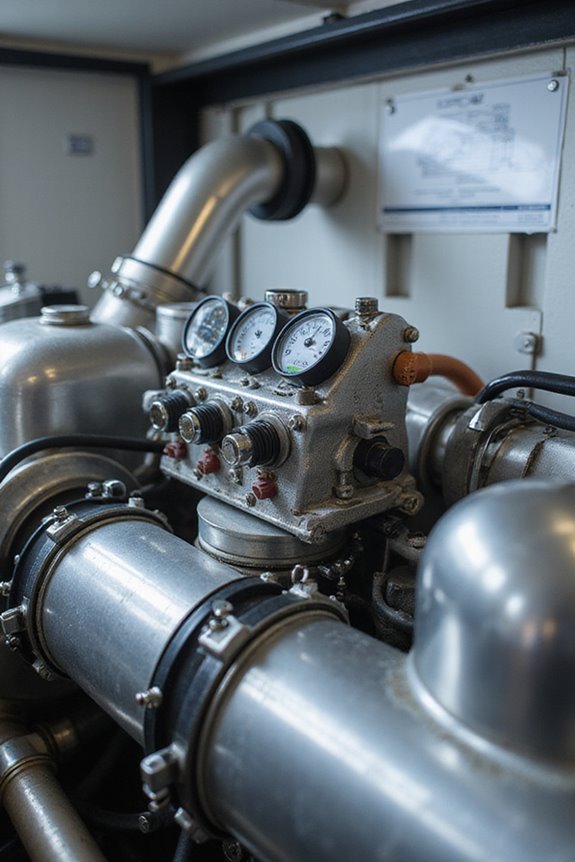

Essential Components of Yacht Engine Room Ventilation Systems

Since a yacht’s engine room is fundamentally its beating heart, the ventilation system components have to be spot on to keep everything running smoothly. We rely on efficient cooling mechanisms like high-volume fans and air diverters to remove heat and maintain intake efficiency—after all, engines crave both cooling air and combustion air. Intake systems must supply fresh air consistently, while exhaust fans whisk away hot, trapped air. Ducting plays a quiet but essential role, directing airflow precisely where it’s needed. And let’s not forget ventilation screens that keep pesky debris or sea spray out without sacrificing performance. Together, these components create a well-oiled machine (pun intended) that safeguards the engine’s health and boosts overall yacht reliability. Ready to plunge into airflow calculations next?

Calculating Proper Vent Area for Optimal Airflow

Because getting the vent area right is essential, let’s explore how we calculate the proper size to keep your yacht’s engine room breathing easy. Vent area calculations usually start with horsepower—we divide total horsepower by 3.3 square inches to find a minimum size. But hold on, we add 20% more to offset ducting resistance like louvers or bends that slow airflow, ensuring smoother ventilation. Got twin engines? Double that vent area! Manufacturers like Cummins offer formulas considering engine air intake, helping us fine-tune airflow optimization. Remember, all intake and exhaust openings combined must meet or exceed required minimums per USCG standards, or your system risks inefficiency. So, with these calculations and a bit of care, your engine room stays cool, happy, and performing just right. Not bad, right?

Managing Temperature and Moisture in Engine Rooms

When it comes to keeping your yacht’s engine room comfortable and efficient, managing temperature and moisture isn’t just a nice-to-have—it’s essential. We all know overheating can cause chaos, so temperature regulation is key. Ideally, the engine room shouldn’t be more than 30°F hotter than outside. Cooling systems using seawater keep things humming smoothly, while directing cool air to air cleaners prevents hot spots. Now, moisture control—ever thought about how humidity could invite corrosion? It’s a sneaky enemy. Using proper air filtration and heating intake air just above the dew point stops water buildup and icing. Plus, effective drainage systems help keep moisture away from sensitive gear. So, aren’t these temperature and moisture strategies just the ticket for long-lasting, reliable engine rooms?

Enhancing Engine Performance Through Ventilation

While good ventilation might not sound like the flashiest way to boost engine power, it’s actually a game-changer for yacht performance. Think of airflow dynamics as the unseen lane that keeps your engine running cool and efficient. Proper ventilation guarantees your engine doesn’t starve for air, preventing power loss and keeping fuel efficiency in check—a key part of performance tuning. We want crisp, cool air flowing low into the engine room while managing Delta T, the temperature difference that impacts how well your engine operates. Plus, the right airflow helps cool essential components, extending their life and avoiding overheating drama. So, by paying attention to ventilation details like fan placement and duct size, we’re giving our engines the fresh air they need to perform their best.

Safety Standards and Regulatory Compliance for Ventilation

Although ventilation might seem like just a technical detail, it’s actually an essential piece of the safety puzzle for any yacht owner or enthusiast. Staying on top of regulatory updates isn’t fun, but it’s vital—we need to guarantee our engine rooms meet U.S. Coast Guard standards, like proper exhaust blower capacity and clear labeling near ignition switches. Ever wondered why compliance audits can feel like a boat’s version of a pop quiz? They confirm our ventilation systems prevent dangerous fuel vapor buildup and keep compartment temperatures in check, usually not exceeding a 30°F difference from outside. So, embracing these safety standards isn’t just about ticking boxes—it’s about protecting everyone aboard, giving us peace of mind while we’re enjoying the waves. After all, safe venting is smooth sailing!

Addressing Common Ventilation Challenges in Yachts

Since proper ventilation is one of those things that can quietly make or break your yacht’s engine performance, we’ve got to tackle the common challenges head-on. Ventilation troubleshooting often shows us that many yachts suffer from undersized vents or poor duct routing, causing engines to “starve” for air and overheat. Ever wonder why your engine room feels like a sauna? Poor airflow measurement and design—like placing both inlets and exhausts high—can seriously reduce efficiency. We also need to watch out for blocked vents or damaged ducts causing resistance and heat buildup. Regularly checking and clearing vents keeps your engines happy and prevents silent damage. After all, good airflow isn’t just a luxury, it’s what keeps your yacht running smooth and cool!

Frequently Asked Questions

How Often Should Engine Room Ventilation Fans Be Replaced?

We should plan for a fan lifespan of 5 to 10 years, with a replacement frequency closer to 5 years if conditions are harsh. Together, let’s stay proactive in maintaining ideal ventilation and safety aboard.

Can Smart Sensors Integrate With Ventilation Control Units?

It is understood that smart technology boosts system reliability, so yes, sensor integration lets us automate ventilation controls. Together, we create safer, more efficient spaces by seamlessly monitoring conditions through real-time data and responsive adjustments.

What Materials Best Resist Marine Corrosion in Ventilation Ducts?

It is understood that marine corrosion’s tough, but stainless steel and fiberglass composites really stand strong together. Their durability and resistance keep our ventilation ducts reliable, so we’re all set for lasting protection in harsh seawater environments.

How to Minimize Vibration Transmission From Fans to Hull?

We can minimize vibration transmission by installing fan isolators and vibration dampening mounts. Together, these components absorb fan-induced vibrations, preventing them from reaching the hull—helping us create a quieter, more comfortable environment aboard.

Are Solar-Powered Ventilation Systems Viable for Yachts?

Imagine Sunreef Yachts cutting energy costs considerably—that’s solar efficiency at work. We can embrace solar-powered ventilation, achieving great energy savings while fostering a sustainable community that values innovation and shared responsibility on every voyage we take together.