When it comes to portlight opening mechanisms, we’ve got a handful to choose from—hinged windows that swing open like a friendly door, sliding types perfect for tight spaces, and friction hinges that let you prop the window open just right. Frames usually use corrosion-resistant metals like stainless steel or aluminum, keeping them shipshape in salty air. Plus, locking mechanisms guarantee these little windows don’t slam shut unexpectedly. Curious about which setup suits your vessel best? We’ve got more to share!

Key Takeaways

- Portlight opening mechanisms include hinged, sliding, friction, fixed, and hybrid types catering to various functional and spatial needs.

- Friction hinges allow precise positioning and secure holding without additional stays or struts, enhancing usability.

- Hinged portlights offer simple operation, security, and ease of maintenance through swinging movement.

- Sliding mechanisms provide a modern look and are ideal for tight spaces where swinging is impractical.

- Locking mechanisms, often stainless steel, prevent unexpected closure and ensure safety during marine conditions.

Types of Portlight Opening Mechanisms

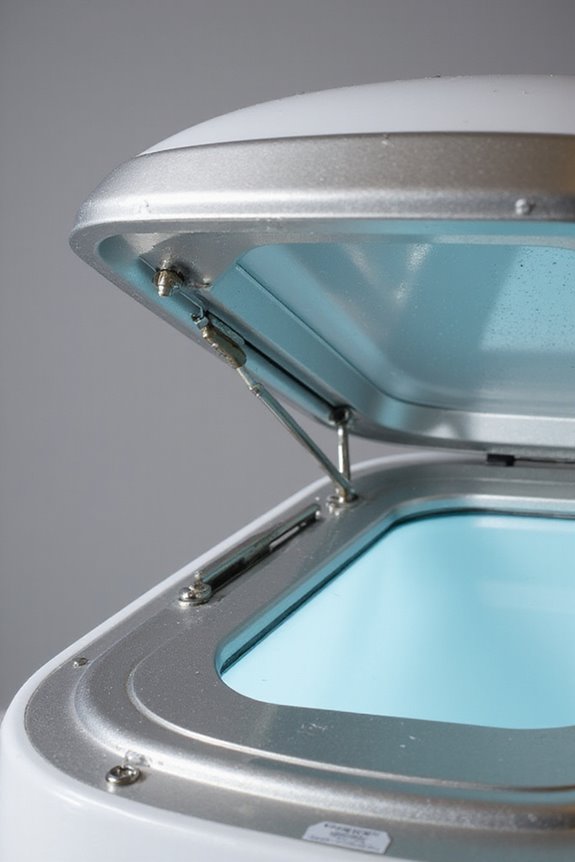

When it comes to portlight opening mechanisms, we’ve got a handful of popular options that each bring their own perks to the table. The hinged advantages are clear—simple, secure, and easy to maintain, letting your window swing open like a friendly invitation. Sliding aesthetics offer a sleek, modern vibe, perfect for tight spaces where every inch counts. Then there’s the friction benefits: friction hinges let you prop windows open anywhere, no need for stays or struts—talk about convenience! Of course, fixed applications serve those who just want light in without fuss—solid and reliable. For those craving uniqueness, hybrid solutions mix features for custom dimensions and use needs. Plus, round designs and flush mounting benefits help your portlights fit snugly and look smashing, blending style with utility. Cool, right?

Materials Used in Portlight Frames

Choosing the right materials for portlight frames is like picking the perfect outfit—they need to look good, perform well, and stand up to whatever comes their way. We lean on durable metals like stainless steel and aluminum because they resist corrosion—crucial near salty seas—and keep frame durability high. Brass adds a classic, polished touch if style matters, while modern composite materials boost strength without adding weight. When it comes to glazing options, acrylic and polycarbonate sheets are popular for being lightweight and impact-resistant, yet safety glass is a go-to for tough, dependable clarity. So, whether you’re after rugged reliability or sleek aesthetics, understanding these materials helps us make smart choices together—because no one wants a leaky, flaky portlight ruining their view or their day, right?

Classification and Strength Standards of Portlights

Since portlights aren’t just fancy windows on your vessel, understanding their classification and strength standards is key to keeping everything shipshape—and safe. We need to follow strict regulatory compliance, especially for vessels over 150 gross tons. Did you know portlights below the bulkhead deck must meet watertight standards? That means either non-opening ports or opening ones that can be tightly secured with special nuts and bolts requiring unique tools—talk about security! Classification societies, like Lloyd’s Register, guarantee all portlights pass type approval, so you’re not left guessing about strength or durability. Plus, portlight sills have precise height rules to prevent any splash party inside your cabin. Together, these rules make certain our portlights don’t just look good but hold up under pressure and protect from leaks. Now, that’s peace of mind.

Design Features Influencing Portlight Operation

While portlights might seem straightforward at first glance, the design features that influence how they operate are actually pretty clever and worth a closer look. For instance, friction hinges offer precise positioning and hold the window open without extra hardware—talk about user ergonomics making life easier! Have you noticed how lightweight alloy frames not only stand up to marine weather but enhance portlight aesthetics with their sleek finishes? Plus, locking mechanisms—often stainless steel—make sure your portlight won’t swing shut unexpectedly, a real safety bonus. We also appreciate how adjustable friction systems allow smooth, tailored opening angles, improving functionality without bulk. And let’s not forget, flush designs and customizable glazing options keep things stylish and easy to clean. Together, these features create portlights that are as user-friendly as they are visually appealing.

Comparison of Swinging and Sliding Portlights

We’ve just looked at the clever design features that make portlights work smoothly, but how do different styles measure up when it comes to real-world use? Swinging portlights add a classic touch and usually seal up tight, which is great for safety considerations like keeping water and noise out. However, they need clear space to open fully, so they’re not the best fit in tight spots. Sliding portlights save space by gliding horizontally along tracks, making them perfect for snug cabins, though their seals might not be as tight, raising some questions about leaks and security. When choosing, think about your aesthetic choices and where you’ll install them—do you prefer tradition and tight seals or space-saving convenience? It’s a trade-off we all face on the water.

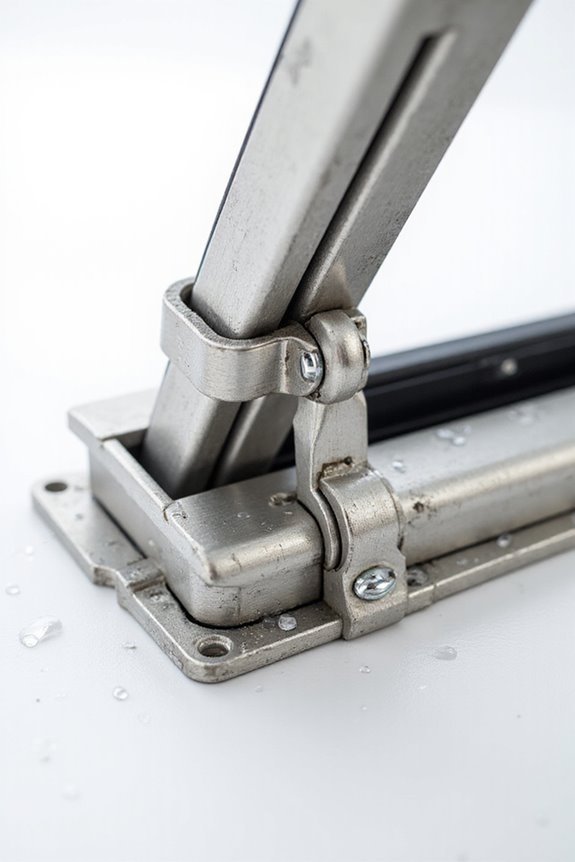

Benefits of Friction Hinges in Modern Designs

Even though hinges might not be the star players on a boat, friction hinges for portlights quietly earn their keep by offering a blend of durability and control that’s hard to beat. One key friction hinge advantage is how they let us position portlights at any angle—no more awkward fully open or shut states. This not only feels smoother but adds serious safety features by preventing sudden slamming, which protects fingers and keeps our gear intact. Plus, made from corrosion-resistant stainless steel, they shrug off saltwater and humidity like champs, cutting down on our maintenance headaches. Sure, they’re best for small to medium hatches, but when installed right, friction hinges give long-lasting, reliable performance that makes opening and closing portlights feel like second nature. Who doesn’t want that?

Clamp and Deadlight Covers for Weather Protection

After appreciating how friction hinges give us smooth control over portlight openings, it’s time to talk about the heavy-duty armor protecting those openings when the weather turns nasty. Clamp and deadlight covers are our trusty defenders, crafted from marine-grade materials like bronze, steel, and tempered glass. They’re designed for effective weather sealing, ensuring water stays out even in rough seas—because nobody wants a soggy cabin, right? Deadlight covers act as solid shields, hinged for quick closure, while clamp covers offer handy quick-action handles and adjustable openings for fresh air without letting the rain sneak in. Plus, these covers meet strict marine standards, so you know they’ll hold up well. Together, they balance protection and convenience—keeping us dry and safe, no matter what the ocean throws our way.

Applications of Opening Portlights on Vessels

Although opening portlights might seem like a small detail, they play a surprisingly big role onboard any vessel. We all appreciate their ventilation benefits, which keep cabins fresh by letting in airflow while reducing humidity and pesky condensation. Ever wondered how they stay open without extra hands? That’s the magic of friction hinges. Beyond comfort, some portlights double as emergency egress points, offering a vital backup escape route in tight spots. This dual function blends safety with everyday convenience, making them indispensable. Plus, they flood interiors with natural light, lifting spirits on long days at sea. With sleek designs and smart materials resisting corrosion, these portlights fit a variety of vessels, making our time aboard safer and more pleasant too. Who knew such little windows could do so much?

Installation Methods for Different Portlight Types

Once we’ve seen how opening portlights add fresh air, light, and safety to our vessels, let’s get into how these handy windows actually get installed. Different portlight types require distinct installation techniques. Mechanically fastened ones rely on screws and butyl tape for a watertight seal, but we must handle fastener heads carefully to avoid damage. Adhesive-bonded portlights call for clean surfaces and evenly applied spacers under flanges. Tape-bonded types, using high-strength foam tapes, offer a fastener-free option, reducing cracking risks and simplifying portlight adjustments. Frameless or glass-bonder portlights need precise surface prep and structural adhesive for a sleek look, usually on rigid substrates. For custom or retrofitting projects, resizing openings with jigs or routers guarantees perfect fits. Any clever tips from your experience with installation techniques?

Maintenance Practices for Reliable Portlight Performance

When it comes to keeping our portlights in tip-top shape, a little regular maintenance goes a long way—trust me, nobody wants a fogged-up or leaky window ruining a sunny day on the water. So, how do we do it? First, mastering good cleaning techniques is key; we recommend using gentle soaps and soft cloths to avoid scratching acrylic or polycarbonate. Next, let’s talk sealant inspection—this step can’t be skipped. Regularly check for cracks or wear in the silicone sealants, especially around edges where leaks sneak in. If you spot any damage, it’s best to replace sealants promptly to keep moisture at bay. By staying on top of these maintenance basics together, we make certain our portlights not only last but shine bright every voyage.

Frequently Asked Questions

How Do Portlight Opening Mechanisms Affect Vessel Energy Efficiency?

It is understood that portlight opening mechanisms impact energy consumption by managing airflow effectively. When sealed well, they reduce heat loss and gain, helping us keep comfortable onboard while lowering energy use—something we all value in efficient vessels.

Can Portlight Mechanisms Be Automated for Remote Operation?

Yes, we can embrace remote control for portlights by integrating automation technology. Though it requires smart engineering and careful planning, together we’ll enhance convenience and safety, joining a community advancing vessel innovation and ease.

What Are the Noise Levels Produced During Portlight Operation?

It is understood that portlight operational sounds can be noticeable, but with proper noise insulation, we can minimize disturbances. Together, we can create a quieter environment by choosing materials and designs that reduce mechanical noise during use.

How Do Portlight Designs Accommodate Accessibility for Disabled Users?

We guarantee portlight design features include lever handles, tactile markings, and motorized options, refined through user testing with disabled individuals, so everyone feels valued and can comfortably access and operate portlights without barriers.

Are There Environmental Impacts Associated With Different Portlight Materials?

We see that material durability influences environmental sustainability greatly. Choosing longer-lasting portlight materials like steel or fiberglass helps us reduce waste and energy use, fostering a shared commitment to protecting our environment together through smarter, sustainable choices.