Keeping your boat’s heat exchanger in good shape means regular checks for leaks, corrosion, and blockages—think of it as giving your engine a cool hug. Watch for odd noises or temperature drops; they’re warning signs of trouble. We use chemical and mechanical cleaning methods to tackle fouling and scale effectively, especially since seawater loves to cause corrosion. Knowing your heat exchanger type helps, too. Want to avoid breakdowns and keep cruising smoothly? There’s plenty more on how to manage this essential system.

Key Takeaways

- Regular inspections prevent corrosion, leaks, and fouling, ensuring efficient heat transfer and reliable engine cooling on your boat.

- Monitor for signs of trouble like abnormal noises, temperature drops, and fluid leaks to detect heat exchanger issues early.

- Understand your heat exchanger type—shell and tube, plate, or plate-fin—to apply proper maintenance and cleaning techniques.

- Clean the heat exchanger periodically using chemical descaling and mechanical methods to remove mineral deposits and grime effectively.

- Follow a maintenance schedule with monthly checks and thorough servicing every 1,500 hours or annually for optimal performance.

Importance of Regular Heat Exchanger Maintenance on Boats

Even though heat exchangers might not be the first thing that comes to mind when we think about boat maintenance, they’re actually pretty important for keeping things running smoothly out on the water. Taking preventive measures with regular heat exchanger maintenance offers big benefits—think of it as giving your boat’s engine a spa day. When we stay on top of cleaning and inspections, we avoid nasty issues like corrosion and fouling, which can quietly sabotage performance. Plus, proper upkeep helps maintain efficient heat transfer, keeping engines cool and functioning effectively. This means fewer breakdowns and better fuel efficiency—both welcome perks for any boater. So, if you want your boat to stay the reliable companion it is, regular heat exchanger care isn’t optional; it’s a must. Let’s keep our vessels cruising without surprise hiccups!

Identifying Common Signs of Heat Exchanger Problems

When it comes to keeping your boat’s heat exchanger in top shape, spotting the warning signs early can save you a ton of hassle down the line. We need to watch for fouling indicators like increased pressure drops or a sudden drop in temperature performance—these often hint at plate blockages or marine growth. Ever heard odd banging or hissing noises? That’s usually a red flag for internal issues, and trust us, ignoring it won’t make it go away. Leak detection is another biggie; pooling fluids around the exchanger or cross-contamination between seawater and coolant often mean corrosion or gasket failures. By staying alert to these signs, we keep things running smoothly and avoid costly breakdowns. After all, nobody wants their boat acting up mid-adventure, right?

Types of Heat Exchangers Found in Marine Applications

Now that we recognize how to spot trouble signs in a heat exchanger, it makes sense to get familiar with the types of exchangers you’ll come across on boats. In marine applications, the most common heat exchanger types include shell and tube, plate, and plate-fin designs. Shell and tube exchangers handle heavy-duty cooling, often in engine rooms, but they can be bulky and need regular cleaning. Plate heat exchangers are compact and perfect for HVAC or freshwater cooling, though they have pressure limits. Plate-fin types are lighter and efficient, often found in specialized systems but less so in main engines. It’s like choosing the right tool for the job: each type suits different needs onboard. Knowing these will make servicing easier and keep your boat running smoothly.

Recommended Maintenance Schedule for Marine Heat Exchangers

A solid maintenance schedule is key to keeping your marine heat exchanger in tip-top shape and avoiding costly downtime. We recommend sticking to a clear maintenance checklist, including monthly inspections for leaks or corrosion and checking coolant levels before long trips. Don’t forget to clean the raw water strainer regularly to prevent blockages—a small chore with big payoff! When it comes to service intervals, aim for a thorough service every 1,500 hours or annually, whichever comes first. This keeps performance steady and helps spot issues early. Of course, following manufacturer guidelines isn’t just a suggestion; it’s our best bet at extending your system’s life. Think of it as routine check-ups for your boat’s cooling heart—neglect them, and things can get cool in a bad way!

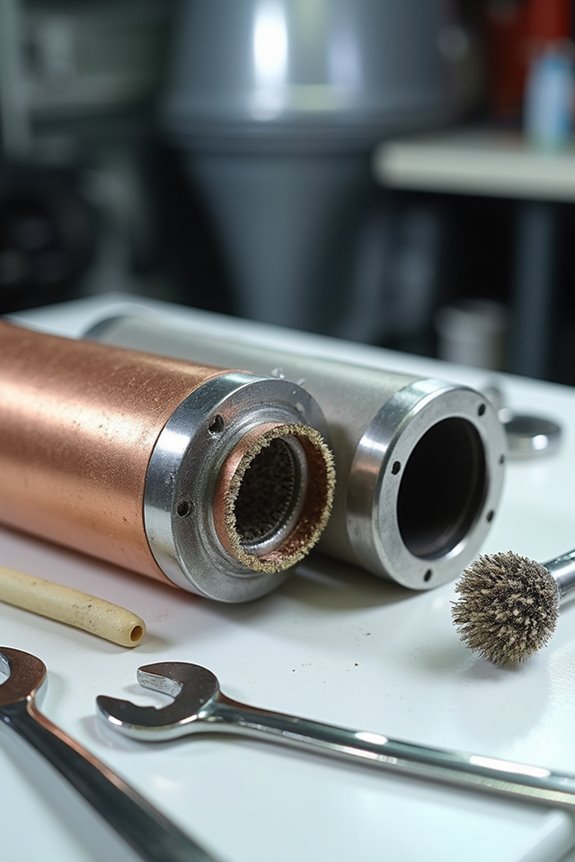

Cleaning Techniques Suitable for Boat Heat Exchangers

Keeping up with your heat exchanger’s maintenance schedule is a smart move—but what about the nitty-gritty of cleaning it? When it comes to boat heat exchangers, we usually lean on two main approaches: chemical descaling techniques and mechanical cleaning methods. Chemical descaling uses acid-based solutions to dissolve stubborn mineral deposits—think of it as a deep clean that gets into tiny crevices. Mechanical cleaning, on the other hand, involves brushes or scrapers to physically remove grime, perfect when deposits are tougher. Sometimes, we combine both for a thorough job. Just remember, not all cleaning solutions play nice with every material, so it pays to be cautious. Have we convinced you yet? A little care goes a long way toward keeping your heat exchanger in shipshape and ready for smooth sailing.

Handling Corrosion and Fouling in Sea Water-Cooled Systems

While seawater cooling is fantastic for keeping boat engines from overheating, it does bring along some pesky challenges—mainly corrosion and fouling. To tackle corrosion prevention, we need to choose corrosion-resistant materials like stainless steel and apply coatings that act as shields against the salty sea. Ever heard of galvanic corrosion? That happens when different metals meet, so matching materials carefully helps avoid those electrochemical feuds. For fouling management, chlorination and pH control play big roles, keeping marine growth at bay and ensuring smooth flow through heat exchangers. Plus, cathodic protection systems—like sacrificial anodes—are like bodyguards for your metal parts. Staying on top of these strategies means your heat exchanger stays healthy longer, keeping your boat running cool and smooth on every trip.

Tools and Safety Measures for Heat Exchanger Servicing

Since servicing heat exchangers on boats involves some tricky spots and delicate parts, having the right tools and safety measures is key to getting the job done well and without mishaps. When it comes to tool selection, things like high-pressure waterjetting and rotary nozzles make cleaning more efficient, while electric torque controllers and hydraulic stub pullers speed up installation and repair. But tools alone won’t keep us safe—that’s where safety protocols shine. Wearing proper PPE, following lockout-tagout systems, and using automated or remotely operated cleaning gear help minimize risks. Ventilation and confined space rules? Non-negotiable. After all, we want to work smart, stay safe, and keep our boats running smoothly—without turning maintenance into a high-seas adventure in disaster!

Record Keeping and Emergency Repair Strategies for Boaters

Although heat exchanger maintenance might not be the most thrilling part of boating, having a solid system for record keeping and emergency repairs can save us from stress—and costly repairs—down the line. Keeping detailed records of maintenance schedules, component replacements, coolant levels, and performance data helps us spot trends before they become problems. It’s like having a health journal for our boat’s cooling system. But what about when things go sideways? Having a plan for emergency repairs—carrying spare parts, basic tools, and knowing quick fixes like sealers or epoxy putty—gives us confidence out there. And hey, we all know when it’s time to call in the pros. Good record keeping paired with smart emergency strategies keeps our boats running smoothly, no matter what surprises the sea throws our way.

Frequently Asked Questions

Can I Service My Boat’S Heat Exchanger Myself or Should I Hire a Professional?

We can tackle DIY maintenance if we comprehend marine systems and have the right tools, but when issues get complex or persistent, it’s smart to trust professional services. Together, we guarantee our boat stays safe and running smoothly.

What Types of Coolant Are Best for Marine Heat Exchangers?

When choosing coolant types for marine heat exchangers, we stick to those meeting marine specifications, like seawater or glycol solutions. These guarantee corrosion resistance and efficient cooling, keeping our boats running smoothly while protecting our shared love for the sea.

How Can I Prevent Heat Exchanger Damage During Winter Storage?

Like tucking our boat in for a deep sleep, winterization tips mean thorough draining and antifreeze application to prevent freeze damage. Together, we guarantee every nook’s protected, so our heat exchanger wakes ready for adventure next spring.

Are Aftermarket Heat Exchanger Parts Reliable Replacements for OEM Components?

It is understood aftermarket reliability varies, but many find these parts perform well compared to OEM components. While OEM guarantees fit and quality, trusted aftermarket brands offer a solid, cost-effective alternative that fits our boating community’s needs.

What Is the Impact of Saltwater Versus Freshwater on Heat Exchanger Lifespan?

It is understood that saltwater corrosion shortens heat exchanger lifespan thanks to scale buildup and harsh conditions. Freshwater efficiency gives us longer-lasting, simpler systems. Together, understanding these helps us choose the right setup and extend our boat’s performance.