When we talk about load-bearing hooks on boats and yachts, we mean those trusty bits of hardware that handle heavy loads like rigging lines, anchors, and emergency releases. They come in types like heavy-duty ramshorn hooks, swivel hooks to prevent line twisting, and quick release hooks for fast emergencies. Made from tough, corrosion-resistant materials like marine-grade stainless steel, they need regular care—think fresh-water rinses and light greasing—to stay reliable. Curious how these hooks keep us safe and efficient out on the water? Let’s explore that together.

Key Takeaways

- Load-bearing hooks come in types like ramshorn, swivel, pulley, quick release, and off-load release, each serving specific rigging and safety roles.

- Marine-grade stainless steel and high tensile carbon steel ensure hooks are strong, corrosion-resistant, and durable under harsh marine conditions.

- Regular maintenance includes rinsing with fresh water, light lubrication, and inspections to prevent wear, corrosion, and ensure reliability.

- Proper crew training focuses on hook selection, safe attachment, load balancing, inspection, and emergency release procedures.

- Consistent safety practices and well-maintained hooks enhance operational efficiency, extend equipment lifespan, and build crew confidence on board.

Types of Load-Bearing Hooks Used in Marine Environments

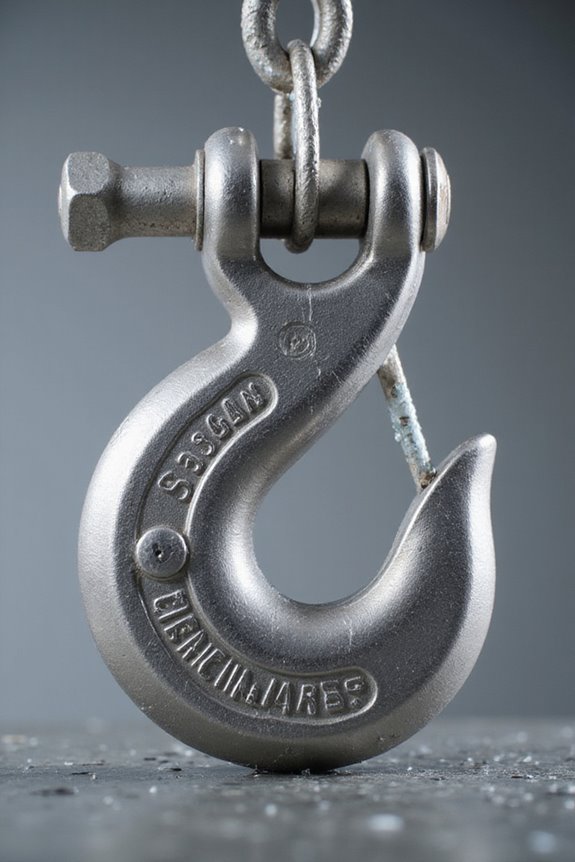

When it comes to marine environments, the types of load-bearing hooks we use can make a huge difference in safety and efficiency—because let’s face it, not all hooks are created equal. We’ve got several hook types tailored to different tasks, like the heavy-duty ramshorn hooks with their double-horned design for extra stability, or versatile single hooks perfect where space is tight. Double hooks help distribute loads with ease, while swivel hooks keep things from twisting, making rigging smoother. Don’t forget pulley hooks, essential for yacht mast rigging—they keep lines running slick. Key hook features like safety latches can prevent accidental load drops, which is a big deal when we’re working around water. Knowing these options helps us choose the right hook, making marine operations safer and more efficient for everyone involved.

Materials and Construction Standards for Marine Hooks

Picking the right type of load-bearing hook is only half the story—we also recognize what these hooks are made of and how they’re put together to handle the tough marine conditions. Marine hook materials like high tensile carbon steel and marine-grade stainless steel offer strength and resist corrosion, an essential combo for salty environments. Construction standards play a big role, too; hooks undergo welding per ASTM guidelines and fatiguing tests ensuring they can handle repeated stress without waving a white flag. Ever wondered how those hooks avoid surprise failures? They’re rigorously tested, including magnetic particle inspections and load checks certified by experts. Plus, elastomeric blocks absorb impact, preventing wear and those pesky sparks. When we recognize these details, we’re really part of the crew ensuring safety and reliability on the water.

Off-Load Release Hooks and Their Operational Role

Although load-bearing hooks are essential for securing lifeboats, off-load release hooks play a unique and crucial role once the boat hits the water. These hooks use clever off load mechanics: they stay locked under load but release automatically when that load drops to zero—usually triggered by water pressure or a hydrostatic piston. Talk about smart! This design keeps release safety front and center, preventing accidental drops mid-air. Ever wonder how crews manage in rough seas? Off-load hooks aren’t ideal there—they need calm waters for safe detachment, and sometimes manual release is necessary if the automatic system hiccups. Regular maintenance is a must to keep things running smoothly. So, while off-load release hooks might sound simple, they’re actually lifesavers that blend safety with smart engineering.

Quick Release Hooks: Safety and Efficiency Benefits

Off-load release hooks have their place in safely lowering lifeboats, but when it comes to managing mooring lines quickly and reliably, quick release hooks really take the spotlight. They let us disconnect lines instantly in emergencies, cutting down accident risks and keeping crew safer—no more wrestling with stubborn knots or hardware. Plus, their remote release options mean we can act from a safe distance if things get rough, boosting safety without slowing us down. Beyond safety, quick release hooks ramp up mooring efficiency by speeding up line handling and lowering labor intensity—faster, simpler, and less strain on everyone involved. Think of these hooks as your dependable crew member: always ready to release tension and keep operations smooth, whether you’re docking a yacht or managing heavy commercial lines. Convenient, reliable, and a real time-saver.

Corrosion Resistance and Durability Factors in Saltwater

When we’re out on the water, battling salty spray and relentless sun, our gear’s ability to resist corrosion and stay durable is more vital than ever. So, what keeps our load-bearing hooks in tip-top shape? It starts with smart material selection criteria—grade 316 stainless steel, with that trusty molybdenum content, offers stellar corrosion resistance against harsh chloride ions. Corrosion prevention strategies don’t stop there; coatings like galvanization and polished finishes add extra armor. We also consider durability factors: strong alloys and smart designs with safety latches help hooks handle tough loads and weather swings without giving up. Plus, regular maintenance? Absolutely critical for longevity. Together, these steps guarantee our hooks perform reliably, proving that with the right choices, even salty seas can’t rain on our boating parade. Additionally, using 316 stainless steel in various marine applications enhances the overall durability and performance of our equipment.

Load Capacity Ratings and Safety Testing Protocols

Since our load-bearing hooks are the unsung heroes keeping everything secure on board, it’s crucial we comprehend exactly how much weight they can safely handle. Load capacity ratings aren’t just numbers—they define the maximum load a hook can bear, often tested well beyond normal conditions to guarantee safety. Have you ever wondered how these ratings are verified? Safety testing protocols like static and dynamic load tests simulate real-life stresses, checking that hooks won’t fail under pressure. We also rely on safety factors, sometimes as high as 3:1, adding a cushion of security. Regular inspections and compliance with international standards, such as IMO and SOLAS guidelines, keep us confident in our equipment. So, next time you clip on a hook, know it’s passed rigorous testing to keep us safe on the water.

Applications of Load-Bearing Hooks in Yachting and Boating

Five common ways load-bearing hooks play an important role on any boat or yacht might surprise you. From docking and mooring to rescue operations, these hooks are our unsung heroes. Proper hook installation techniques guarantee they’re positioned perfectly to handle heavy loads, while solid load assessment strategies help us avoid any “uh-oh” moments. Need to secure fenders or manage tangled lines? Hooks have got your back. They also shine in launch and recovery tasks, keeping rescue crafts safe and stable. Have you ever thought about their role in anchor management? It’s vital—helping us hold steady in all conditions. Together, understanding these applications fosters a safer, smoother boating experience, making every journey feel like part of the crew. Who knew hooks could be this dependable, right?

Innovations in Hook Design and Material Technology

We’ve seen how load-bearing hooks play a surprisingly diverse role in yachting and boating, but have you ever thought about what makes these trusty tools tick? Modern hooks use 316 marine-grade stainless steel, which means less rust and more reliability in salty conditions. Cool, right? The real magic lies in improved hook functionality—swivel bearings reduce torsion, making load positioning smoother and safer. Plus, safety mechanisms have stepped up big time. Automatic double-locking systems guarantee hooks won’t accidentally release under pressure, while sleek, snag-free designs keep everything running smoothly without unexpected stops. With ergonomic safety handles and specialized coatings, these hooks not only last longer but make our jobs easier and safer at sea. So, it’s more than metal—it’s thoughtful engineering keeping us secure out there.

Maintenance Best Practices for Marine Load Hooks

Though load-bearing hooks look sturdy enough to handle rough seas on their own, they actually depend a lot on regular TLC from us to keep performing well. You might wonder, how often should we do hook cleaning? Ideally, after every use—freshwater rinse and mild detergent help wipe away salt and grime that can cause corrosion. Lubrication techniques are just as key: a light marine-grade grease or spray oil keeps moving parts like swivel hooks and lock slides friction-free and happy. Just don’t overdo it—too much lube invites dirt, making things stickier than a clam bake in July! Regular inspections help catch wear before it sneaks up on us, so let’s keep logs and follow manufacturer guidelines. After all, well-maintained hooks are the unsung heroes of safe boating.

Enhancing Safety Through Proper Hook Usage and Training

When it comes to using load-bearing hooks on boats and yachts, safety doesn’t just happen—it’s something we build through proper habits and know-how. To keep everyone safe, crew safety must be our top priority, starting with thorough hook training. Why guess when you can learn? Regular training programs help us identify the right hook for each task and teach how to inspect them for wear or corrosion. We also make sure hooks are securely attached and backed up by safety chains—because one weak link isn’t an option out here. Plus, practicing load balancing and emergency procedures keeps us ready for anything. With consistent hook training, we not only protect our gear but also strengthen our team’s confidence and safety culture on board. Who’s in for safer seas?

Frequently Asked Questions

Can Load-Bearing Hooks Be Customized for Specific Boat Sizes or Types?

It is understood custom hook designs matter for boat compatibility, so we work together to tailor hooks perfectly for your boat size and type. That way, you’re always confident your gear fits safely and efficiently with us.

How Do Temperature Extremes Affect the Performance of Marine Hooks?

Just like steel tested in fire, we understand temperature impact can cause performance degradation in marine hooks. Together, we must choose materials wisely to withstand extremes, ensuring safety and strength for every voyage we set out on.

Are There Eco-Friendly Alternatives to Traditional Stainless Steel Hooks?

We’re embracing biodegradable materials and sustainable manufacturing to create eco-friendly boat hooks. Together, we can reduce our environmental impact while enjoying boating, fostering a community that values both performance and protecting our waters.

What Is the Average Lifespan of a Load-Bearing Hook in Commercial Boating?

It is understood that the average lifespan of load-bearing hooks in commercial boating often depends on load bearing materials and diligent hook maintenance. Together, embracing proper care lets us extend their durability and keep safety at the forefront for our community.

How Do Load-Bearing Hooks Interact With Advanced Mooring Automation Systems?

We’re excited to share how load bearing hook integration guarantees seamless automation system compatibility, letting us monitor loads in real-time and enhance safety together. This connection makes our mooring operations smoother and more efficient for everyone involved.