We understand keeping your boat’s engine healthy can feel like steering through uncharted waters, but an oil analysis program is your trusty compass. By testing oil for wear metals, viscosity, and contamination, it detects problems early—think of it as a health check for your engine. This saves you costly repairs and downtime, plus helps plan maintenance smarter. Curious how sampling works or choosing the right lab? Stick around, because there’s plenty more to make you an oil analysis pro.

Key Takeaways

- Oil analysis programs monitor engine oil health to detect wear and contamination early, preventing costly boat engine repairs.

- Key tests include spectral examination, viscosity, flash point, insolubles, and chemical analyses to assess oil and engine condition.

- Regular oil analysis extends engine life, reduces unexpected breakdowns, and optimizes maintenance scheduling for boats and yachts.

- Proper oil sampling with calibrated tools ensures accurate analysis and reliable diagnostic results for marine engines.

- Choose accredited labs with ASTM standards, fast turnaround, and expert interpretation for trustworthy oil analysis reports.

What Is an Oil Analysis Program?

Think of an oil analysis program as a health check-up for your boat’s engine—only instead of a stethoscope, we’re using science to peek inside the oil. Together, we monitor oil health and contamination levels to spot signs of potential trouble before things go south. This program isn’t just about testing oil; it’s about understanding whether your engine’s running smoothly within expected parameters. By regularly sampling and analyzing oil, we can detect early wear or unwanted contaminants that might sneak in—like water or soot—that could damage your engine. It’s a team effort, requiring proper sampling with calibrated tools to keep our data reliable. So, want to reduce downtime and extend your engine’s life? This is the proactive approach we all need to embrace.

Key Tests Performed in Oil Analysis

Although oil analysis might sound like a bunch of lab jargon, it really boils down to a set of key tests that tell us exactly what’s happening inside your boat’s engine. One important test, spectral examination, detects wear metals from parts like bearings and pistons, while also identifying contamination sources such as dirt or coolant. Viscosity testing checks if the oil flows properly, revealing fuel dilution or additive breakdown. Flash point analysis helps spot volatile contaminations by measuring the temperature at which oil vapors ignite, signaling trouble if it’s too low or high. Insolubles testing measures harmful particles and combustion byproducts, and chemical tests track oil oxidation and acidity levels. Together, these tests give us a detailed picture, helping keep your marine engine running smooth and safe.

Benefits of Regular Oil Analysis for Marine Engines

A regular oil analysis program for your boat’s engine is like having a health check-up, but for your marine machinery. We all want our engines to run smoothly and last longer, right? By catching issues early through oil analysis, we can detect contamination or abnormal wear before it turns into a costly headache. This early detection not only helps prevent unexpected breakdowns but also extends the machinery lifespan, keeping our vessels reliable for many voyages. Plus, who enjoys surprise repairs when out at sea? With regular oil checks, we schedule maintenance smarter, save money on major fixes, and even optimize lubricant use. Think of it as giving your engine a little TLC—because keeping it healthy means more time cruising, less time in the dock.

Interpreting an Oil Analysis Report

Getting your engine’s oil analyzed regularly is one thing, but reading the report yourself? That’s where the real power lies. Together, we’ll learn how to spot signs of oil degradation—like viscosity changes or oxidation—that hint our engine oil’s losing its mojo. Then, let’s peek at contamination sources: fuel dilution shows injector problems, water suggests leaks, and sodium or silicon point to coolant or dirt sneaking in. Don’t miss those wear metals—iron and aluminum levels tell us which parts might be wearing out. A low flash point or odd insoluble amounts? Those are red flags for trouble. It might seem like a secret code, but once we get the hang of it, interpreting these reports helps us keep our boats running smoothly and avoid costly surprises out at sea. Pretty neat, right?

Selection Criteria for an Oil Analysis Laboratory

Picking the right oil analysis lab can feel like sorting through a sea of options—so where do we even start? First off, we want labs with solid laboratory accreditation, preferably ISO 17025, which assures us their testing methodologies are reliable and standardized. It’s like having a trusted captain aboard. We also look for labs using standardized test methods like ASTM or well-validated in-house techniques, ensuring our samples get the right attention. Quick turnaround times matter, too—because waiting weeks for results isn’t exactly fun, right? And don’t forget about labs with experienced technicians; their expertise turns data into insight. Choosing wisely means fewer surprises and smoother sailing for our boats and yachts. So let’s pick a lab that’s steady, skilled, and responsive—our engines will thank us!

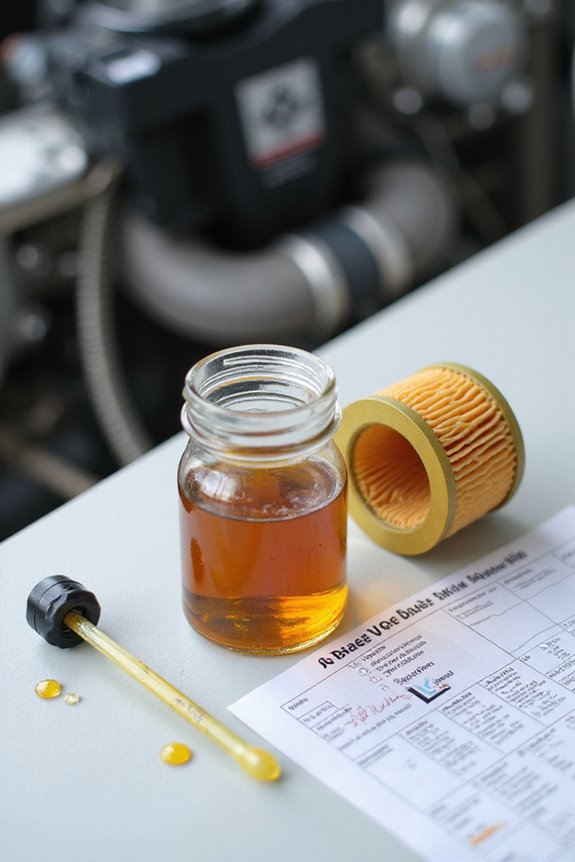

Sampling Procedures and Best Practices

Although oil analysis might sound like just another chore, nailing the sampling process is where the magic really begins. We’re talking about perfect sampling timing—grab that sample when the engine’s warmed up, around 80°C or after a good 20-30 minutes of running. This guarantees wear particles are well suspended, giving us the real story. But don’t be tempted to sample right after an oil change; contaminants may be diluted, fooling us into thinking everything’s peachy. Contamination prevention is key too: always use a clean, dedicated container, and avoid dunking probes in dirty spots like the oil pan bottom. Want a solid sample? Pull it from the dipstick tube with a clean pump or during an oil drain—but steer clear of exhaust or cooling water spots. Together, these practices keep your analysis honest and valuable.

How Oil Analysis Supports Maintenance Planning

While oil analysis might seem like just another routine check, it’s actually a powerful tool that helps us plan maintenance smarter, not harder. By regularly monitoring the oil condition, we can catch tiny wear signs before they turn into big headaches. This means we don’t have to stick to rigid schedules that might waste time or money. Instead, maintenance frequency adjusts based on real engine needs, which feels way more efficient—plus, who likes fixing surprises mid-voyage? Tailoring our maintenance like this extends machinery life and reduces costly downtime. It’s like having a crystal ball for our boat’s health—predictive, precise, and proactive. So, embracing oil analysis means fewer emergency repairs and more smooth sailing, which sounds like a plan we all want to be part of.

Record Keeping and Trend Analysis in Oil Monitoring

To really make the most of oil analysis, keeping solid records and spotting trends over time is where the magic happens. We rely on neat, consistent record keeping to preserve data integrity—no guessing games here! Trend visualization, often through graphs or charts, gives us a clear picture of how oil quality and engine health evolve. Isn’t it rewarding to spot a small problem before it becomes a big headache? Using digital tools makes storing and reviewing oil samples simple, while regular sampling keeps our data meaningful. Plus, proper labeling and training guarantee we don’t mix up results and skew the analysis. In the end, these habits help us extend equipment life and avoid surprise repairs—just the teamwork our vessels deserve.

Frequently Asked Questions

How Often Should Oil Samples Be Taken on Recreational Boats?

Picture oil sampling frequency as the heartbeat of our boats. For recreational vessels, we keep it steady by testing every 50 hours during active seasons and adjust sampling around seasonal maintenance to stay in sync with our shared passion.

Can Oil Analysis Detect Fuel Contamination Before Engine Damage Occurs?

It is understood fuel testing plays a key role in spotting contamination early, helping us protect engine health before damage sets in. By working together, we guarantee our vessels stay reliable and ready for every adventure.

What Equipment Is Needed Onboard to Properly Collect Oil Samples?

Picture us carefully drawing oil with essential oil sampling tools—portable pumps, pitot tubes, and brass button probes—in hand. Together, we’ll master sample collection procedures, ensuring precise, safe oil sampling that keeps our engines running smoothly.

Are There Specific Oil Brands Recommended for Better Analysis Accuracy?

When choosing specific oil brands, we find that using those with well-documented formulations boosts analysis accuracy. Sticking together with trusted brands helps us all get reliable results, ensuring we maintain our engines confidently and consistently.

How Does Water Contamination Show up in Oil Analysis Results?

When water sources contaminate oil, we see changes like increased acidity, viscosity shifts, and corrosion signs in analysis results. Together, we can identify these contamination effects early to protect our engine’s health and performance.