Let’s talk underwater exhaust systems on yachts—they quietly blend hot engine fumes with cooling water, cutting noise and emissions while boosting your boat’s style. Key parts like the mixing elbow and waterlock muffler work together to keep engines safe from seawater and reduce vibrations. Plus, smart designs manage back pressure and flow so your ride stays smooth. We stick to safety rules too, obviously! Curious how it all fits and functions? Stick around to uncover those details.

Key Takeaways

- Underwater exhaust systems reduce noise and eliminate bulky mufflers, enhancing yacht comfort and aesthetics.

- They mix exhaust gases with cooling water using mixing elbows, lowering temperature and sound levels.

- Waterlock mufflers prevent seawater backflow, protecting the engine and maintaining efficient operation.

- Hydrodynamic fittings optimize exhaust flow, minimizing drag and back pressure for smooth cruising.

- Compliance with U.S. Coast Guard and ABYC standards ensures safety, proper sealing, and CO detection onboard.

Purpose and Benefits of Underwater Exhaust Systems

Although underwater exhaust systems might sound like just a techy upgrade, they actually bring a bunch of practical benefits that we all appreciate once we grasp them. First off, they improve our vessels’ design aesthetics by eliminating bulky, noisy mufflers cluttering engine rooms and exterior transoms. Plus, by releasing exhaust below the waterline, these systems cut down noise, making our time aboard much more comfortable — who wants to cruise feeling like they’re in a jet engine, right? We also can’t ignore the environmental impact: cooling and dispersing exhaust underwater reduces airborne pollutants and foul odors near marinas, helping keep our favorite spots cleaner. So, these systems not only boost comfort and style but also show we care about preserving our shared waters—a win-win for all of us.

Key Components of the Exhaust System

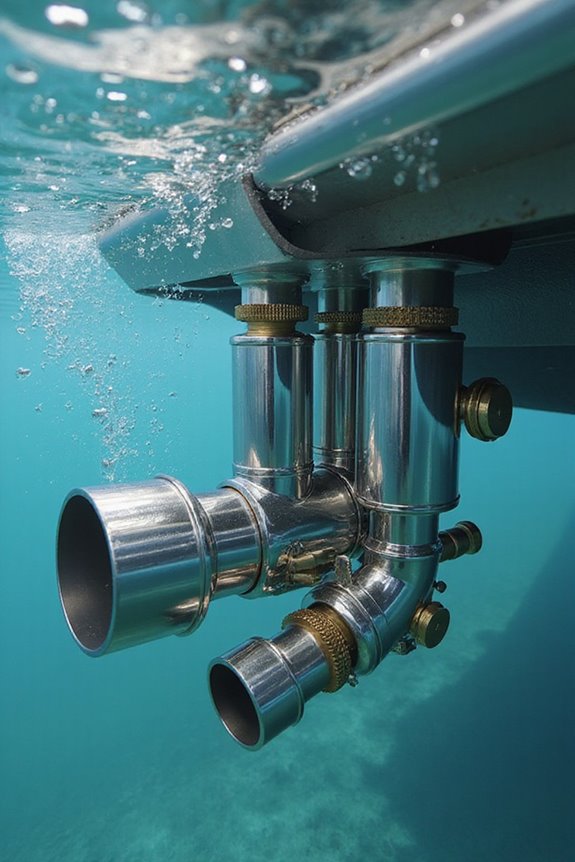

When it comes to underwater exhaust systems, a handful of key components work together to keep things running smoothly and quietly below the waterline. First, the mixing elbow combines hot engine exhaust with cooling water, helping lower temperatures while cutting noise—sound attenuation is a big deal here. Then we have the waterlock muffler, crafted from corrosion-resistant exhaust materials like fiberglass composites, which dampens noise and stops seawater from sneaking back into the engine—a true gatekeeper! Don’t forget the gooseneck and thru-hull fittings; they guarantee water stays out while providing a seawater-tight exit for exhaust gases. Finally, exhaust manifolds and risers handle the hot gases, demanding sturdy high-temp metals. Together, these parts form an underwater exhaust system that’s reliable, efficient, and surprisingly quiet—pretty neat, right?

How Underwater Exhaust Systems Operate

Since underwater exhaust systems push engine gases out beneath the waterline, they work a bit differently than the exhausts you might be used to seeing on boats. At cruising speeds, a clever venturi effect helps pull exhaust gases out smoothly, boosting operational efficiency while keeping backpressure low. When idling or moving slowly, a bypass outlet kicks in to prevent engine strain. Here’s the cool part: exhaust gases mix with water inside the system, which lowers temperature and offers natural sound suppression by muffling noise underwater—much quieter than your typical smokestack. Plus, water-lift mufflers and flexible hoses help dampen vibrations further. It all adds up to a system designed to protect your engine while letting you enjoy quieter, smoother cruising. Who knew exhausts could be so smart?

Hydraulic and Structural Design Elements

Now that we’ve got a handle on how underwater exhaust systems move gases quietly and efficiently, let’s talk about what makes their design tick beneath the surface. Hydrodynamic fittings play a starring role, shaping exhaust flow with foil and bullet shapes that reduce drag while creating just enough turbulence to help disperse gases underwater. Ever wonder how muffler design fits into this? Well, mufflers aren’t just noise cops; their layout balances gas volume and water cooling to keep things smooth and efficient. Plus, smart structural choices, like mounting exhaust outlets below the waterline and using bypass pipes, tackle space limits and keep back pressure low without drowning your engine. It’s a careful mix of hydraulics and structure working in harmony—yacht exhaust engineering at its finest.

Engine Safety and Back Pressure Management

Although underwater exhaust systems work hard behind the scenes, keeping your engine safe and managing back pressure is where the real magic happens. We all know excessive back pressure can sap engine power and cause unnecessary wear. That’s why proper engine maintenance—like regularly checking exhaust components and adjusting bypass valves—is key. Ever wondered why your engine sometimes feels sluggish? It might be back pressure building up due to a misadjusted bypass system or clogged muffler. Forward movement creates low pressure zones that help push exhaust out efficiently, but without good design, this doesn’t work well. So, keeping a close eye on temperature and back pressure readings isn’t just good practice—it’s essential to avoid costly damage. Trust us, your engine will thank you for the care.

Cooling and Water Flow Considerations

While underwater exhaust systems might seem like a simple pipe and pump setup, the cooling and water flow inside them are actually pretty fascinating—and essential for keeping everything running smoothly. We rely on seawater pumped at high flow rates to efficiently mix with hot exhaust gases, bringing temperatures down from fiery 400°C to a much safer 40–50°C. This clever water management not only protects hoses and components but maintains cooling efficiency across the system. Ever wonder how water doesn’t flood your engine? That’s where design features like the mixing elbow injection point and gooseneck come in, preventing backflow and unwanted water ingress. Keeping the flow steady and unobstructed is key; after all, a sluggish water supply could mean serious heat trouble—and nobody wants that onboard!

Compliance With Maritime Safety Standards

Keeping underwater exhaust systems cool and flowing right is just one piece of the puzzle—we also have to play by the rules set by maritime safety standards. Steering through these regulatory challenges can feel like decoding a secret map, but it’s essential for safety compliance and smooth sailing. From U.S. Coast Guard rules to ABYC standards, we’re ensuring exhaust hoses are tightly clamped and corrosion-resistant, preventing nasty backflow surprises. Ever thought about carbon monoxide? Sealing bulkheads and installing detectors help keep everyone onboard safe. Noise limits and muffler use aren’t just suggestions—they’re law, so modifications need careful handling to avoid penalties. Together, we stay informed and compliant, keeping our yachts safe, quiet, and seaworthy. After all, safety isn’t just smart—it’s our shared responsibility.

Innovations and Customization Opportunities

When it comes to underwater exhaust systems, innovation isn’t just a fancy buzzword—it’s what keeps our boats running smoother, cooler, and quieter than ever before. Thanks to advanced materials like saltwater-resistant stainless steel and proprietary hardcoat insulation, durability and heat management have seriously improved. But here’s where it gets exciting: custom fabrication lets us tailor every component—think exhaust outlets and adjustable backpressure scoops—to match your vessel’s exact needs. We’re not just fitting parts; we’re crafting solutions that boost performance while reducing noise and wear. Plus, retrofitting older boats with these upgrades means you don’t have to buy new to benefit from cutting-edge tech. So, ready to tune your underwater exhaust system to perfection? It’s innovation with a personal touch—and your boat’s best friend.

Frequently Asked Questions

How Does Underwater Exhaust Affect Marine Life and Underwater Noise Levels?

Like ripples in a pond, underwater exhaust stirs our marine ecosystem, increasing CO2 and noise pollution that disrupts life and communication. Together, we must listen and protect these fragile underwater communities from harm’s silent spread.

What Maintenance Routines Are Recommended for Underwater Exhaust Systems?

Let’s prioritize regular maintenance tips and system inspections together, checking hoses, clamps, seacocks, and cleaning outlets. Staying proactive keeps our underwater exhaust systems efficient and protects our shared love for smooth, safe yachting experiences.

Can Underwater Exhaust Systems Be Retrofitted to Older Boats?

It is understood retrofit feasibility depends on space and engine layout, but installation challenges like custom piping and flood prevention can be tricky. Together, we’ll navigate these hurdles and make underwater exhausts work for your older boat confidently.

What Are Common Troubleshooting Steps for Underwater Exhaust System Failures?

Like sailors tuning their compass, we start troubleshooting underwater exhaust troubles by focusing on leak detection and noise reduction. Together, we guarantee smooth voyages by inspecting connections, silencing escape hisses, and restoring harmony to our shared seafaring journeys.

How Do Underwater Exhaust Systems Impact Resale Value of a Yacht?

We’ve noticed that underwater exhaust systems boost yacht aesthetics, aligning with resale trends favoring sleek, quieter vessels. This feature often adds value but can also prompt questions about maintenance complexity from potential buyers in our community.