Keeping your boat’s diesel engine happy means regular visual checks for leaks and belt wear, plus topping off cooling fluids and descaling heat exchangers every couple of years to avoid nasty clogs. Don’t forget fuel—clean filters and fresh fuel prevent those annoying RPM surges or smoky exhausts. We also swap oil and filters regularly, especially before winter storing, when antifreeze and fogging oil protect internal parts. Curious about nailing maintenance schedules and safety checks? Stick with us.

Key Takeaways

- Regularly inspect the engine for leaks, belt wear, corrosion, and debris buildup to ensure reliable operation and early issue detection.

- Maintain the cooling system by flushing coolant every 500 hours, descaling heat exchangers, lubricating impellers, and replacing zinc anodes as needed.

- Manage fuel quality through multi-stage filtration, regular fuel testing, and timely filter replacements to prevent contamination and engine performance issues.

- Perform oil changes every 100 to 300 hours using the correct oil type, always replacing the oil filter to protect engine components.

- Winterize by flushing with antifreeze, adding fuel stabilizer, changing filters, applying fogging oil, and inspecting seals for optimal cold-weather protection.

Regular Inspection and Visual Checks

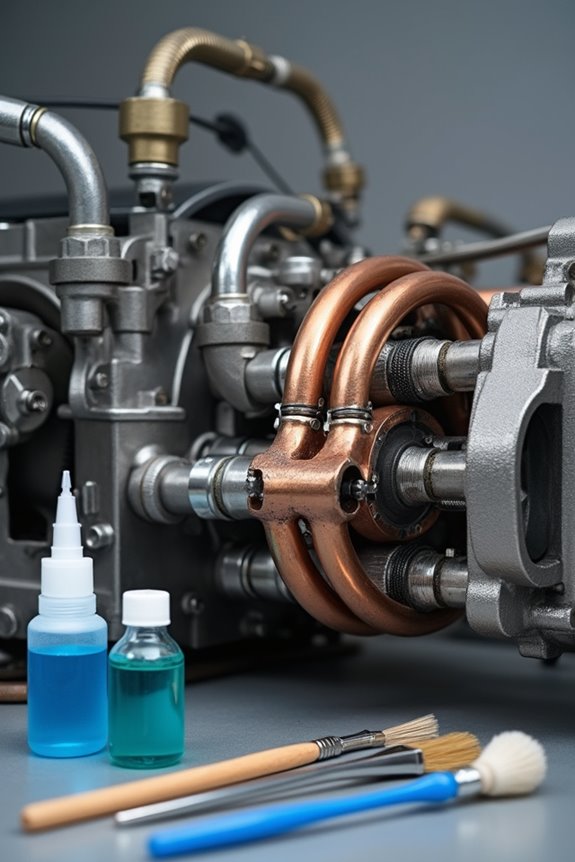

Even if you’re not a certified mechanic, regular visual checks on your boat’s diesel engine can save you a lot of headaches down the line. Let’s start by scouting for engine leaks—any puddles or damp spots in the compartment? These little troublemakers love to sneak up on us. Next, check the belt condition carefully; look for cuts, fraying, or belt dust, which might hint at misalignment or wear. It’s like giving your engine a quick health check. While inspecting, keep an eye out for fuel or oil spills and signs of corrosion or debris buildup. Trust me, these small inspections become second nature and build our confidence in the engine’s reliability. After all, wouldn’t we all prefer smooth sailing without unexpected engine drama?

Cooling System Maintenance and Descaling

There are a handful of key parts in your boat’s cooling system that deserve our attention if we want to keep things running smoothly and avoid those dreaded overheating moments. For starters, performing regular coolant flushing every 500 hours or two years is essential to flush out old antifreeze and contaminants. Don’t forget the heat exchanger — descaling it with the right solution every couple of years helps remove stubborn mineral deposits that slow things down. When it’s time to replace your impeller, let’s give it some impeller lubrication using glycerin or silicone grease, so it slides in smoothly. Oh, and zinc anodes? We should inspect them often and swap them out once over half their thickness is gone to keep corrosion at bay. Staying on top of these keeps our engines happily cool and cruising!

Managing Fuel Systems and Filtration

Since keeping the cooling system in top shape helps our engines run smoothly, it makes sense to give a little attention to the fuel side of things too. Managing fuel systems and filtration is key to avoiding those annoying RPM surges and smoky exhausts we all want to skip. Regular fuel testing lets us catch contamination before it turns into costly repairs. Filtration systems, especially multi-stage setups, do a great job removing water and debris—both nasty culprits that encourage bacterial growth and clog filters. Don’t forget to check your filters regularly and replace them as needed. After all, clean fuel means happier engines and less downtime. Together, staying on top of these fuel management basics keeps us cruising confidently, knowing our diesel heartbeats are pumping pure and strong.

Lubrication Practices and Oil Changes

While we all love hearing the steady hum of a well-tuned diesel engine, keeping that rhythm smooth means paying close attention to lubrication practices and timely oil changes. Choosing the right oil isn’t just a quick pick—lubricant compatibility with your engine matters to prevent premature wear and costly repairs. Synthetic oils, with their resistance to oil degradation under tough marine conditions, often outperform conventional ones. But how often should we change that oil? Most marine diesels suggest oil changes every 100 to 300 hours, depending on usage and engine type. Don’t forget the oil filter; changing it with every oil change is a small step that keeps contaminants from crashing your engine’s party. Together, careful oil choices and regular changes keep our engines cruising happily and reliably.

Seasonal Care: Winterization and De-winterization

Before we tuck our boats and yachts away for the chilly months, giving their diesel engines some seasonal care—known as winterization—is vital to avoid costly headaches later. Our winterization checklist includes flushing the cooling system with non-toxic antifreeze to prevent freezing and corrosion, adding diesel fuel stabilizer to keep fuel fresh, changing filters, and spraying fogging oil inside the intake manifold for internal protection. Don’t forget sealing air intakes and exhaust ports to keep moisture out! When spring calls us back, de winterization tips like inspecting seals, flushing antifreeze, bleeding the fuel system, and running the engine gently help guarantee smooth startups. It’s a bit like prepping your boat for a long winter nap, so when it wakes, it’s lively and ready for adventure. Sound like a plan?

Monitoring Engine Performance and Safety

Although we might not see every twist and turn inside our diesel engines, monitoring their performance closely helps us stay ahead of trouble and enjoy smooth sailing. By using performance analytics, we can track combustion efficiency, fuel injection, and cylinder balance in real time. These insights aren’t just fancy numbers—they’re our early warning system against costly repairs. Plus, keeping up with safety protocols means we reduce emissions and comply with maritime rules like IMO standards, so the environment—and our consciences—stay cleaner. Modern online monitoring systems alert us instantly if something’s off, sparing us the surprise breakdowns no one wants. So, why not embrace these tools? After all, with predictive maintenance and solid safety checks, our engines—and our peace of mind—keep running strong, no matter the waves.

Maintaining Seals, Impellers, and Zinc Anodes

Since our engines rely on a handful of small but mighty parts to run smoothly, taking good care of seals, impellers, and zinc anodes is non-negotiable if we aim to avoid surprises out on the water. Regular seal inspection helps us catch cracks or brittleness, so we can replace them before leaks cause bigger problems. When it comes to impeller replacement, sticking to a yearly or 250-hour schedule guarantees our seawater pumps keep the engine cool—nothing ruins a day faster than overheating. And let’s not forget the zinc anode; it sacrifices itself to protect metal parts from corrosion, so checking it every couple of weeks until we understand its wear rate is a smart move. These maintenance tips may seem small, but they’re the unsung heroes of reliable engines.

Keeping Detailed Maintenance Records and Scheduling

When we keep detailed maintenance records, we’re not just ticking boxes—we’re building a powerful tool to understand our diesel engine’s history and future needs. Good record organization supports smart maintenance strategies, helping us track everything from 50-hour fuel separator drains to annual checks without losing our place in the chaos. Using logs and scheduling tools, like apps or calendars, makes it easier to plan inspections ahead, so we catch small issues before they get expensive. Plus, sharing records with fellow boaters? That’s how we build a community that knows its way around marine diesel care. After all, don’t we all want a smoothly running engine and fewer “Why is the engine making that noise?” moments? Keeping on top of records and schedules is teamwork between us and our boat’s heart.

Frequently Asked Questions

How Do Weather Conditions Affect Diesel Engine Maintenance Schedules?

It is understood weather impact demands seasonal adjustments in our maintenance schedules. Extreme temperatures, humidity, and saltwater exposure all push us to inspect and service our engines more often, ensuring reliability and keeping our shared adventures smooth and safe.

What Are the Best Practices for Managing Battery Health in Marine Engines?

Like tending a glowing lantern, we keep our batteries healthy by vigilant battery charging and corrosion prevention—cleaning terminals, securing connections, and staying connected as a crew, ensuring our power never flickers when we need it most.

How Can I Optimize Fuel Efficiency in Varying Marine Environments?

To optimize fuel efficiency in varying marine environments, we regularly use fuel additives and prioritize precise engine tuning. Together, let’s adapt settings based on conditions, ensuring our engines run smoothly and efficiently—fuel savings and seamless journeys, guaranteed.

What Safety Equipment Should Be Kept Onboard for Engine Emergencies?

Like a trusted crew on a stormy sea, we keep a fire extinguishers checklist handy, alongside emergency signaling devices, ensuring we’re ready for any engine emergency—because together, safety means everyone aboard belongs and thrives.

Are There Specific Maintenance Considerations for Marine Diesel Transmission Systems?

It is understood that keeping transmission fluid at proper levels is key, along with regularly checking gear ratios for smooth shifts. Together, we can guarantee our marine diesel transmissions run reliably and enjoy smooth sailing every time.